Top-Notch Specialty Die Cutting

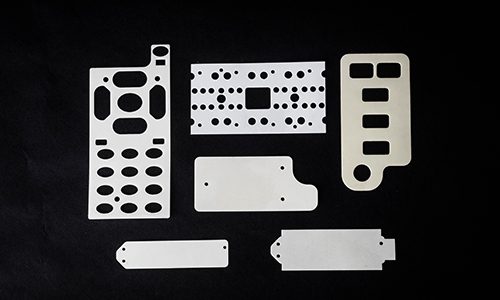

Galleon Decals & Die Cuts is proud to offer high-quality digital die-cutting and blanking services for plastic films, adhesives, and soft metals. Our state-of-the-art technology allows us to provide steel rule, chemically etched, hard tools, and laser cutting services to fulfill our customers’ needs.

Choose Galleon Decals & Die Cuts for high-quality specialty die cutting. Whether you need custom high-resolution digitally printed decals, product labels, or special adhesives, we have you covered.

What We Die Cut

Materials We Die Cut

Testimonials

Single- & Double-Sided Spacers

Spacers for Membrane Switches & Circuit Boards

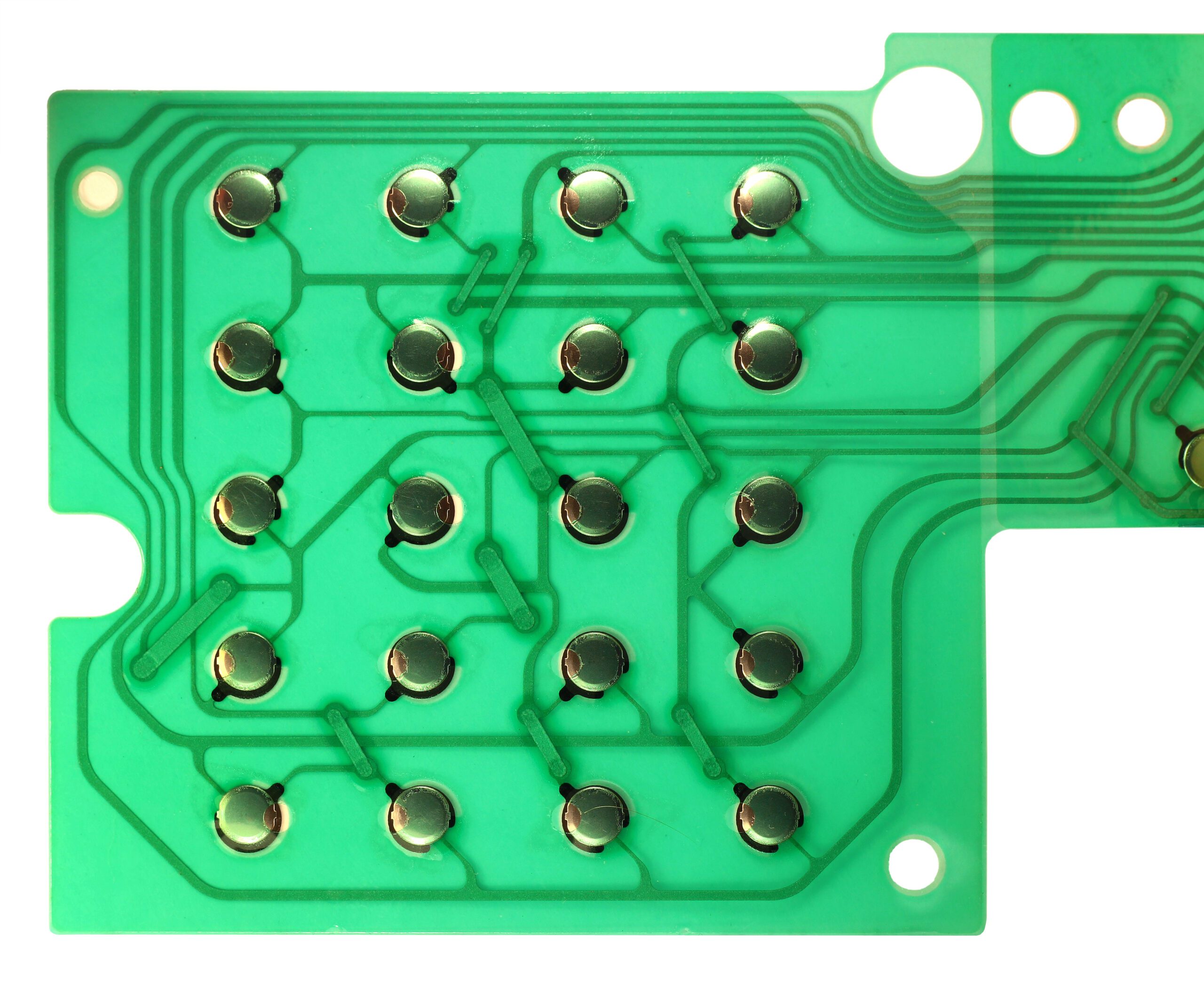

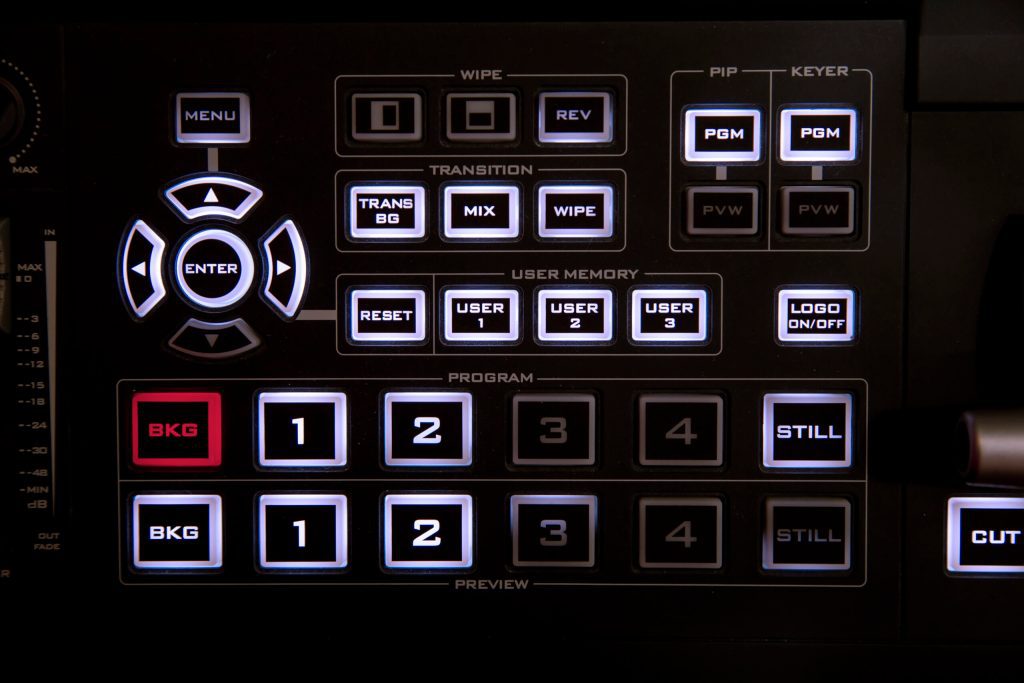

Membrane switches are made up of several layers, including a graphic overlay, a single or double-sided spacer, the printed circuit board, an adhesive layer, and a connector tail. The spacer is a crucial component of the membrane switch, as it provides the necessary separation between the graphic overlay and the printed circuit board.

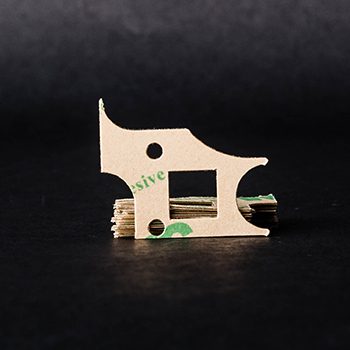

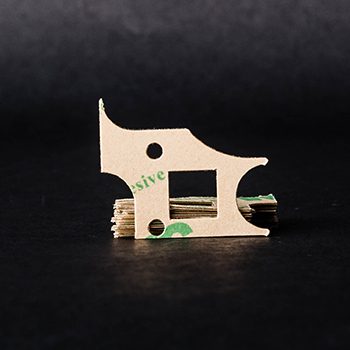

Galleon Decals & Die Cuts specializes in the custom die-cutting of single or double-sided spacers, ensuring that your membrane switch is precisely tailored to your needs.

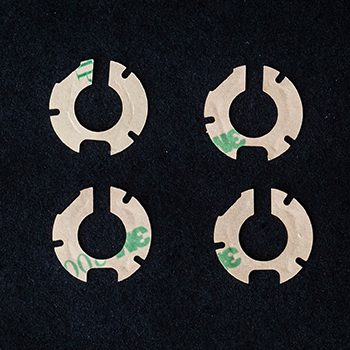

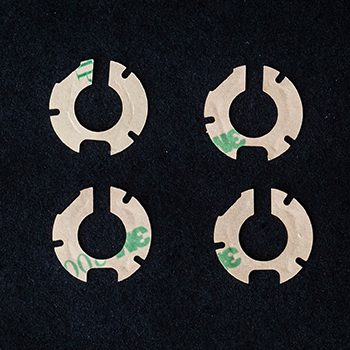

Single-Sided Spacers

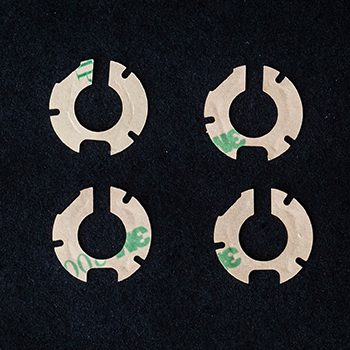

Single-sided spacers are clear or white polyester sheets with adhesive on one side. They are used to hold the tactile metal dome over a printed circuit board in place. These spacers are known as dome retaining sheets (DRS) and are custom die-cut in an array designed to cover the circuit board.

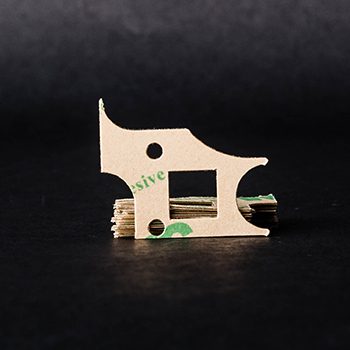

Double-Sided Spacers

Double-sided spacers consist of polyester of a specific thickness with adhesive on both sides. They are designed to bond and provide circuit separation within a membrane switch.

Diffuser & Blackout Material for Backlighting

Backlighting membrane switches can cause hotspots, but there are ways to correct them. Galleon Decals & Die Cuts offers custom die-cut diffuser materials that help correct hotspots to various degrees. Additionally, 3M ESR Film creates a complete blackout. Three known methods for backlighting membrane switches are light-emitting diodes (LED), optical fiber, and electroluminescence. LED is the most common and preferred method.

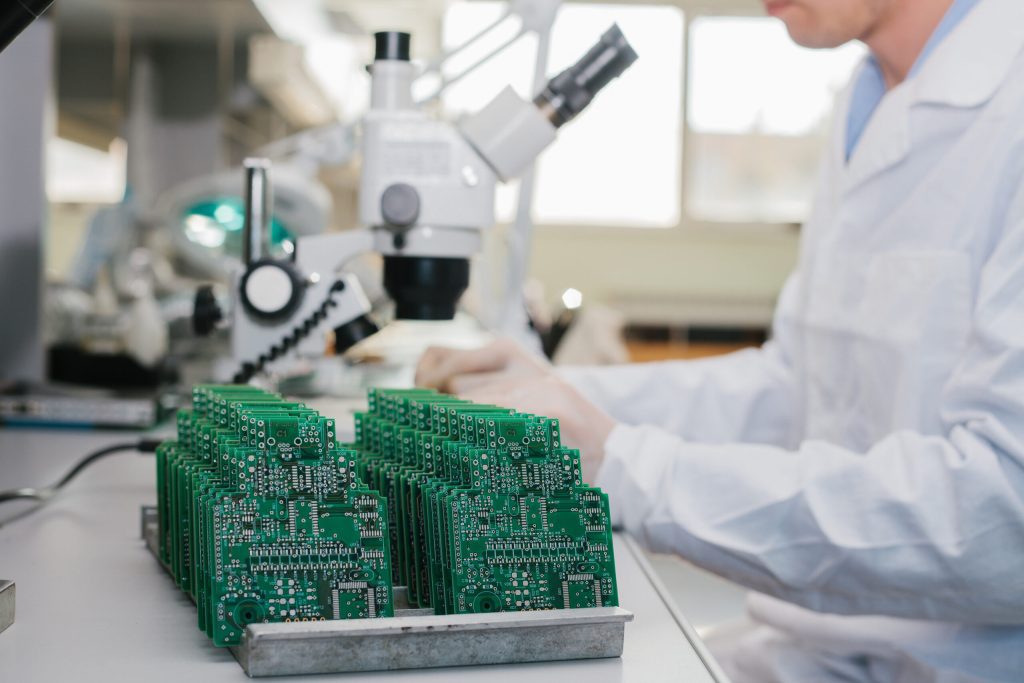

Quality Control & Inspection

At Galleon Decals & Die Cuts, we understand the importance of strict dimension controls for parts. That’s why we provide complete inspection reports to ensure accurate production. Our quality control process follows the Production Part Approval Process (PPAP), which has proven to be a valuable tool for establishing our customers’ confidence and production process.

We use the Image Dimension Measurement System from Keyence for our inspection process. This system has reduced the time and cost needed to perform inspections, keeping your production flowing smoothly. It measures all noted dimensions, automatically records, and calculates Cp and Cpk in seconds. With our inspection reports, you can be confident that your parts meet the necessary dimension controls. Contact us for more information.